|

Thermography

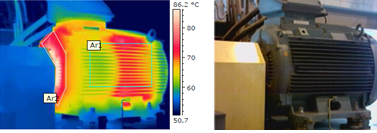

Mechanical Thermography

Mechanical Thermography is the effective tool to identify developing faults in machine components which method is safe and non-intrusive.

All rotating parts generate heat due to friction between components and develops its own thermal profile depends on thermal gradients which relevantly generates infrared radiations signatures can be recognizable by the experienced thermographer.

Cost-effective and with immediate results - An Mechanical Thermography Survey enables you to prevent equipment failures.

Using Thermal Imaging technology to capture heat-generated images - RotoMatrix Infrared Thermography Survey provides an instant, precise, non-contact analysis of plant & machinery condition to highlight faulty components such as bearings, motors, fuses, relays, steam pipes, drive gears & belts.

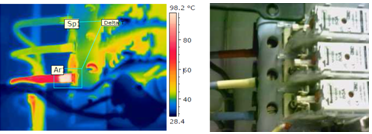

Electrical Thermography

Electrical systems are the most critical items within office buildings and industrial applications. There are considerable benefits to be gained by protecting these systems and reducing unplanned stoppages. Thermography is ideal for carrying out Electrical Safety Inspections, be it to source that loose bus-bar connection or that overloaded component in your main electrical panel.

Infrared technology gives us the ability to see and measure temperatures on defective components and the normal wear, chemical contamination, corrosion, fatigue and faulty assembly in many electrical systems. The resistance or molecular friction produced within these problem areas is visible in the infrared spectrum and visible to the infrared camera. Overheating can occur in virtually all electrical components and hardware including generators, transformers, fuse connections, switchgear, starters, contactors and any other hardware one might imagine.

In transmission and distribution systems thermography surveys can help cut production losses and prevent the eventual failure of these systems.

Call us today on +91 9543339119 or E-mail service@rotomatrix.com

|