|

Condition Monitoring

Condition monitoring is a continuous process of machine health assessment to prevent breakdowns by adopting various

effective techniques such as vibration analysis, Thermography, Lubrication Analysis, Motor Circuit Analysis, Ultrasonic

Analysis and operational parameters study.

Condition monitoring techniques are well proven predictive maintenance approach to early detect machine components developing

problems that leads to unexpected failures well before the next scheduled maintenance outage, saved millions of dollars in

secondary damage, production loss and unnecessary maintenance which has been accepted worldwide for all type of industries.

Every machine develops faults over a period of continuous operations which can be prevented by periodic monitoring, trending

and analysis of data obtained through various techniques results in accordance to respective accepted standard of acceptance

level.

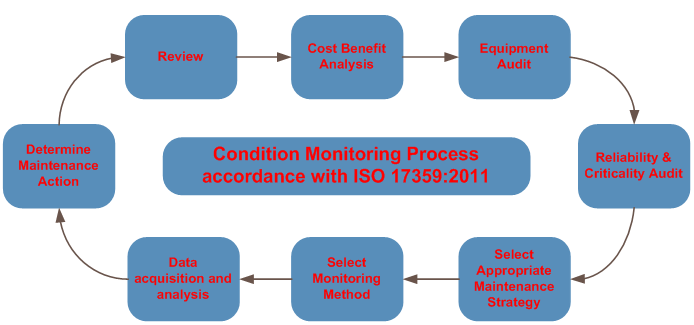

Condition monitoring benefit proves by strict compliance of closed loop process chain.

Condition monitoring Cycle:

Implementation of an effective condition monitoring strategy will strongly help industries to prevent unplanned, costly equipment repairs and downtime. ISO 17359:2011 describes general guidelines for condition monitoring and diagnostics of machines, which procedural and strict implementations apparently works well with realistic benefits.

Call us today on +91 9543339119 or E-mail service@rotomatrix.com

|