Vibration Analysis

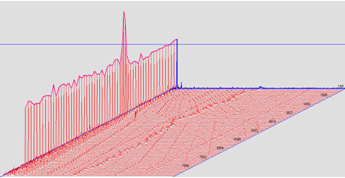

Vibration Analysis is the most recognized key method in condition monitoring which brings out early detection of developing

problems in rotating machineries such as Rotor Imbalance, Looseness, Misalignment, Bearing defects, Gear defects, Flow induced

problem and so on.

Vibration monitoring is performed to assist evaluation of health of the machine during sustained operations. Depending on the

machine type and criticality one or more measurement parameters and suitable monitoring system should be selected.

The objective is to recognize machine health condition in sufficient time to take remedial action before certain defects in the machine parts

significantly decrease equipment operation or fail completely, thereby establishing a cost effective maintenance plan.

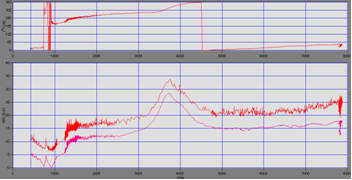

Continuous Vibration data Analysis:

A continuous data collection system is one in which vibration transducers are installed permanently at key locations on the

machine and in which vibration measurements are usually recorded and stored continuously during operation. It

can include automatic vibration monitoring systems with multiplex connections provided that the multiplexing rate is

sufficiently rapid so that no significant data or trends are lost. The data may be processed to provide either broadband or

spectral information which can be compared to previously acquired data by setting alert limits on the stored data.

Continuous data collection system can be installed at the machine site for direct use by the machine operating crew or it can be installed

at remote sites with data transmitted to a central data analysis centre.

Periodic Vibration Data Analysis:

Periodic data collection can be done either by permanently installed online systems or portable systems.

Online periodic system can include automatic vibration monitoring system with multiplexer connections.

Portable monitoring system performs similar function as the continuous online system, but it is less elaborative and less expensive. In this, data can be recorded

periodically either automatically or manually.

RotoMatrix engineers will provide worldwide coverage in house at customer site to perform both offline and online data collection and analysis. Furthermore, we can extend our support by reviewing existing online continuous monitoring data and transient data to get optimum results.

Call us today on +91 9543339119 or E-mail service@rotomatrix.com

|