Advanced NDT Services

Advanced Non-Destructive Testing (NDT) refers to a set of sophisticated techniques and technologies used to inspect and evaluate the integrity of materials, components, or structures without causing any damage or altering their state. These methods are typically more precise, sensitive, and capable of detecting flaws or defects that basic NDT methods might miss. This allows for detecting microscopic defects, such as cracks, voids, or inclusions, which might not be visible with traditional methods.

Advanced Nondestructive Testing (NDT) services incorporate state-of-the-art techniques to assess material integrity and detect flaws with unparalleled precision. These methods include Phased Array Ultrasonic Testing (PAUT), Guided Wave Testing (GWT), and Pulsed Eddy Current (PEC), among others.

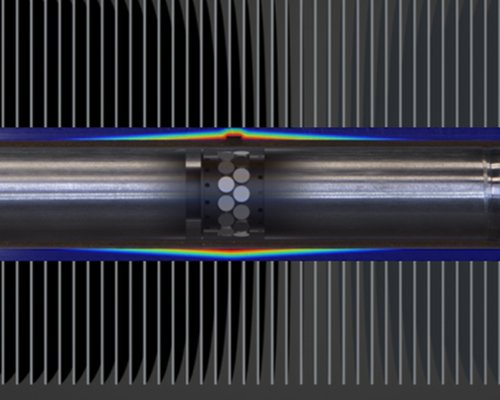

ECA – Eddy Current Array

Eddy Current Array (ECA) is an advanced NDT technique that enhances traditional Eddy Current Testing by utilizing multiple coils arranged in a specific configuration. This setup enables the simultaneous inspection of larger areas without compromising sensitivity, reducing inspection time significantly.

ECA is particularly effective for detecting surface and subsurface defects in complex geometries, such as curved or irregular surfaces, making it highly suitable for aerospace, power generation, and petrochemical applications. Additionally, its ability to provide real-time imaging aids in precise defect characterization.

Eddy Current Array (ECA) testing offers several advantages over conventional Eddy Current Testing (ECT), primarily due to its ability to collect data over a larger area with more detail and in a shorter period. Specific benefits of ECA over traditional ECT:

- Increased Coverage per Scan

- Higher Resolution and Detail

- Faster Inspections

- Better Adaptability to Complex Geometries

- Enhanced Probability of Detection (POD)

- Real-Time Visualization and Imaging

- Reduced Operator Dependency

- Data Archiving and Comparison

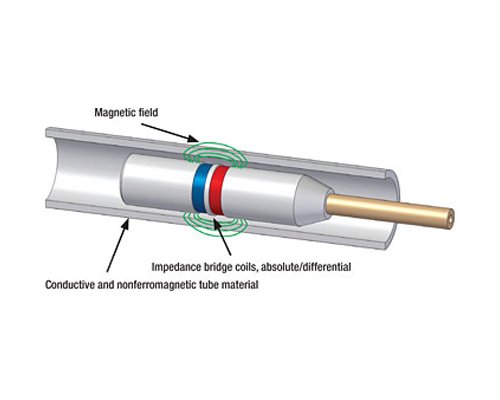

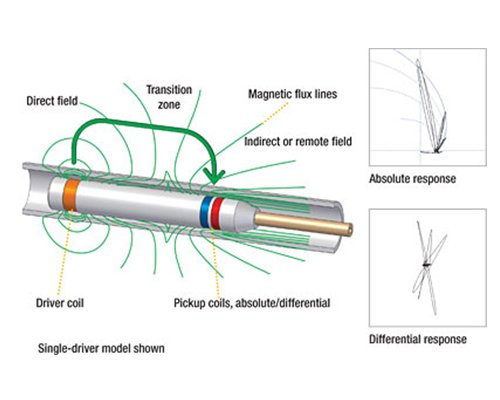

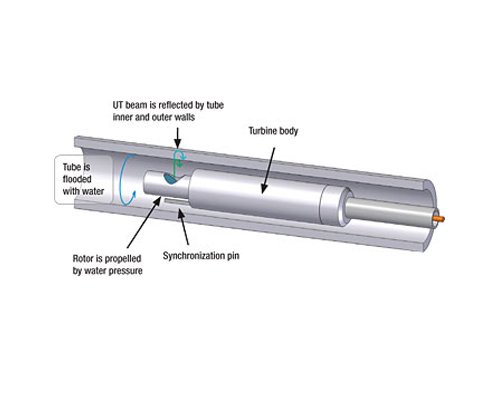

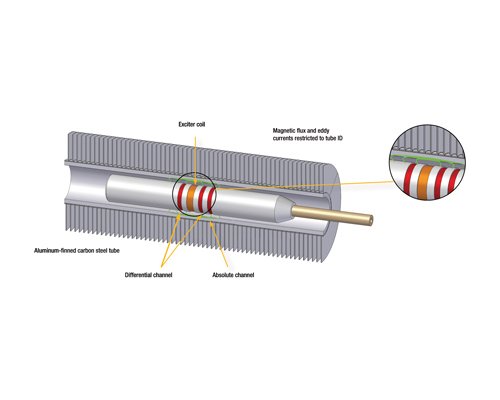

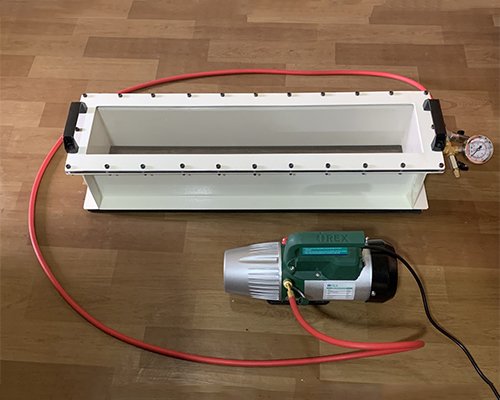

Tubing Eddy Current Array (ECA) is a specialized eddy current testing method used specifically to inspect tubing and pipes, commonly in heat exchangers, boilers, and condensers.

This method is critical in industries such as power generation, petrochemical, and HVAC, where metal tubing is susceptible to various forms of degradation like corrosion, pitting, cracking, and wear. Tubing ECA enhances traditional eddy current testing by using multiple coils arranged in an array that can scan the tubing more thoroughly and quickly, providing comprehensive coverage and high-resolution imaging.

Key Features of Tubing Eddy Current Array

1. Full Circumference Inspection

2. Detection of Small Defects

3. Flexible and Adaptable Probes

4. Increased Speed and Efficiency

5. Real-Time Data Visualization